Contact us for support: 01536 263411

Plug into discounts! With 15% off all products sitewide, because every connection matters!

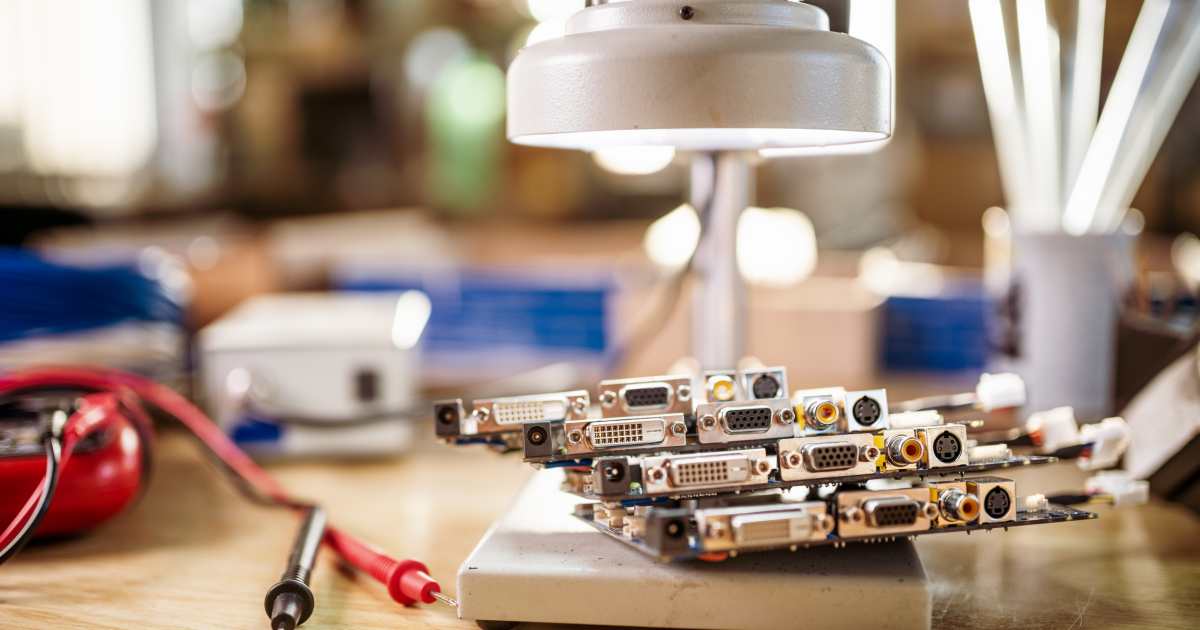

D-Sub connectors play a critical role in electronic and industrial connectivity. Their significance transcends mere function, forming the backbone of essential connections that power and integrate essential systems. From facilitating data transmission to managing power distribution, their role is paramount.

What sets D Sub connectors apart is their unparalleled versatility. They are the chameleons of connectivity, seamlessly integrating into an array of applications. Their ubiquitous presence spans across computing systems, industrial machinery, and various other technological domains. This adaptability speaks volumes about their reliability and adaptiveness in a rapidly advancing technological landscape.

In this blog post, we will dive deep into the world of D-Sub connectors, demystify its components, and discuss their practical applications. Whether you are a tech enthusiast or a professional aiming to broaden your knowledge, this comprehensive guide about D-Sub connectors will offer valuable insight.

So, let’s get started!

At the heart of D Sub connectors lies a design that marries functionality with simplicity. Their distinctive shape, resembling the letter “D,” encompasses a robust shell that safeguards the internal components. Within this shell, a set of pins or sockets form the interface for connection, ensuring secure and reliable contact.

D Sub connectors come in two primary forms: male and female. The male connector features pins that protrude from its body, while the female connector contains matching sockets to receive these pins. This dichotomy establishes a seamless connection, with the male connector typically being the “plug” and the female connector acting as the “receptacle.”

The male connector, with its protruding pins, serves as the interface that inserts into the female connector’s sockets. These connectors often play the role of an output or transmitting end. Conversely, female connectors, with their socket configuration, receive the male pins, serving as the input or receiving end of the connection.

D Sub connectors exhibit various pin configurations, denoted by the number of pins they contain. Common configurations include 9-pin (DE-9), 15-pin (DB-15), 25-pin (DB-25), and higher pin counts, each tailored for specific applications and functionalities. The arrangement of these pins follows industry standards, ensuring compatibility and ease of use across devices and systems.

D Sub connectors have long been a cornerstone of computer hardware. From older VGA (Video Graphics Array) connections to serial and parallel ports, these connectors facilitated crucial links between monitors, printers, external drives, and various peripherals. Although newer interfaces have emerged, D Sub connectors remain relevant in specialised computer applications, providing reliable connectivity.

In addition, D Sub connectors play a significant role in modems, routers, and network devices. They serve as the interface for serial communication ports, allowing seamless connectivity between these devices and external peripherals. Despite the evolution of networking technologies, D Sub connectors continue to serve in specific communication equipment due to their reliability.

Moreover, D Sub connectors are fundamental in instrumentation and control systems across industries. They serve as the backbone for connecting sensors, control panels, and various monitoring devices. Whether in industrial automation, scientific instrumentation, or other control systems, D Sub connectors facilitate the transmission of critical data, enabling precise control and monitoring of processes.

D Sub connectors have entrenched themselves as pivotal components in diverse electronic applications, proving their adaptability and reliability across computer hardware, communication equipment, and sophisticated control systems.

In industrial machinery, automation systems, and robotics, D Sub connectors act as the linchpin of connectivity. They facilitate communication and data exchange between various components within these systems, ensuring seamless operation and control. These connectors play an integral role in linking control units, sensors, actuators, and other critical components.

One of the primary functions of D-sub connectors in industrial settings is connecting peripherals and sensors to central control systems. Whether it’s interfacing with monitoring sensors, feedback devices, or auxiliary equipment, these connectors provide a reliable and standardised interface for seamless integration and data transmission.

Enterprises often opt for a specialised variation of D Sub connectors with Metplas D-Sub Hood within industrial setups. These hoods, with their rugged construction and enhanced protective features, reinforce the reliability of D-sub connectors in demanding industrial environments. They offer heightened durability and shielding, ensuring the connectors remain resilient against harsh conditions and mechanical stress.

Understanding the advantages and considerations of D Sub connectors helps in making informed decisions regarding their application in various contexts, leveraging their strengths while considering potential limitations.

There are an array of D sub connectors with different hoods available in the market. Each has distinct features, sizes, and pin configurations. Below are the different types of D-sub connector hoods and their specific uses across different industries, helping you understand which type is best suited for a particular application.

The Metal D Sub Hood is a protective covering or housing designed specifically for D-Sub connectors, offering enhanced durability and ruggedness, especially in demanding industrial environments. Its specialised hood provides superior shielding against electromagnetic interference (EMI) and radio frequency interference (RFI), safeguarding the connected components from potential signal disturbances that could impact performance.

The Metplas Sub D hood is an innovative solution tailored to fortify and safeguard D Sub connectors within industrial and challenging operational environments. Its protective covering is designed to offer heightened durability and resilience, offering superior protection against external elements like EMI and RFI, mechanical stress, and potential damage. Crafted from high-quality materials, the Metplas D sub hood provides an extra layer of defence for D Sub connectors, prolonging their lifespan and reducing the risk of wear and tear, even in demanding industrial settings.

Plastic Sub D hoods represent the conventional protective covering for D Sub connectors, offering a standard level of protection and enclosure for these connectors across various applications. These hoods, typically made from durable plastic materials, serve as a practical solution for shielding D-Sub connectors in less demanding environments.

While not as resilient against extreme conditions as their metal counterparts, these hoods still offer adequate protection against dust, minor impacts, and moderate mechanical stress. As such, plastic sub-d hoods are suited for environments with lower risks of extreme temperatures, heavy vibrations, or exposure to significant external forces.

D-Sub connectors epitomise the essence of seamless connectivity, intertwining various technological domains into a cohesive network. Their adaptability, durability, and reliability make them an integral part of electronic and industrial landscapes, ensuring the smooth transmission of data and power.

Step into the realm of superior connectivity solutions with Component Buddy. Beyond an extensive array of D Sub connectors, Component Buddy encompasses a comprehensive range of Electronic and Industrial Electrical Components, Cables, and Equipment, offering a one-stop destination for your technological needs.

Are you ready to transform the way you connect and power your systems?

View our shop today to secure your D Sub connectors and fulfil your electronic and industrial electrical components, cables, and equipment needs.

Embrace the power of seamless connections with Component Buddy – your partner in technological excellence.