Contact us for support: 01536 263411

Free Delivery On All Orders During October

Contents

Circular connectors are an indispensable component, seamlessly threading together vital systems and devices in electronic and industrial connectivity. Characterised by their rounded shape and adaptable design, their construction enables robust connections that transmit power, data, and signals efficiently between devices and systems. Despite their ubiquitous presence, the underlying basics and diverse applications of circular connectors often remain underappreciated.

What sets circular connectors apart is their unparalleled versatility. They are not confined to a single domain but find their place in diverse applications. Their adaptability allows them to thrive in environments ranging from aerospace and military applications to medical devices and telecommunications.

In this blog, we aim to shed light on these essential devices, exploring their fundamental principles, various types, and the wide array of applications they serve. Whether you’re an electrical engineer, a tech enthusiast, or simply curious about the inner workings of the devices that surround us, this post is sure to provide insightful knowledge about the indispensable role of circular connectors.

From their basic design to the complex mechanisms they facilitate, let’s take a closer look at the integral role circular connectors play in powering connectivity across numerous industries.

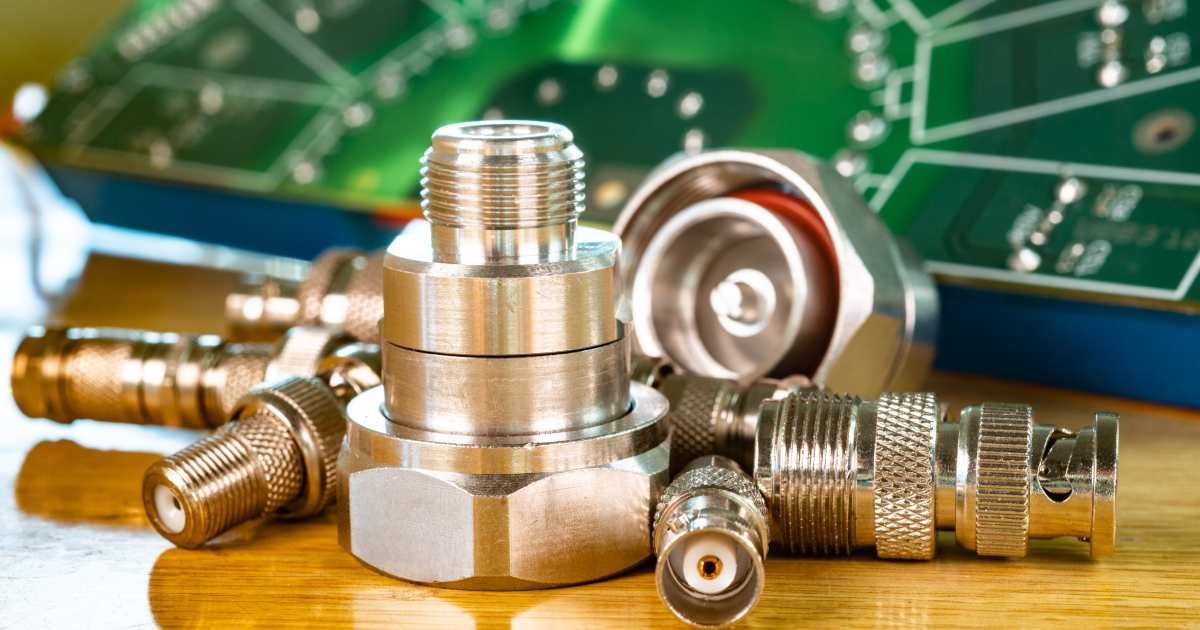

Circular connectors comprise a structured design consisting of a cylindrical housing that encases the essential components. Within this housing, multiple contact points, such as pins and sockets, form the interface for establishing connections. The connectors also feature a coupling mechanism, allowing secure and reliable mating between the male and female parts.

Circular connectors come in a range of sizes and configurations, tailored to meet diverse connectivity needs. They vary in diameter, pin count, and overall form factor, offering flexibility to accommodate specific applications. From miniature connectors used in compact electronics to larger variants employed in industrial setups, the spectrum of sizes ensures adaptability across industries.

Circular connectors span a wide array of types, each engineered to address specific requirements. Some common variations include:

Understanding the structure, variations, and types of circular connectors lays the groundwork for exploring their extensive applications across electronic and industrial landscapes.

Discover the myriad benefits associated with the use of circular connectors in various applications.

Circular connectors are renowned for their durability, constructed with robust materials that withstand mechanical stress and environmental factors. Their sturdy build ensures resilience against vibrations, impact, and temperature variations, guaranteeing consistent performance even in demanding conditions. This durability, coupled with stringent manufacturing standards, contributes to their unwavering reliability in critical applications.

Featuring a user-friendly design, circular connectors offer simplicity in installation and maintenance. Their standardised configurations and coupling mechanisms facilitate easy connections, reducing assembly time and enhancing operational efficiency. Additionally, their modular designs often allow for quick component replacement or upgrades, minimising downtime and streamlining maintenance procedures.

Circular connectors exhibit exceptional versatility, thriving in a spectrum of environments. Whether it’s the controlled environment of a laboratory, the rugged terrain of industrial settings, or even challenging outdoor conditions, these connectors adapt seamlessly. Their ability to withstand moisture, dust, and temperature variations makes them suitable for applications ranging from aerospace and military to medical devices and telecommunications.

Their adaptability extends across diverse applications. Circular connectors serve as the backbone of connectivity in critical systems, including data transmission in communication devices, power supply in industrial machinery, and signal connections in medical equipment. This versatility positions them as the go-to choice for engineers seeking reliable and robust connectivity solutions.

Circular connectors, with their durability, reliability, and adaptability, are crucial components in diverse environments, powering a wide spectrum of applications with unwavering performance.

In this section, we will explore their application in various industries, such as telecommunications, computing, aerospace, and industrial machinery, highlighting their contribution to the seamless operation of complex electronic systems.

Circular connectors play a pivotal role in electronic devices, facilitating efficient data transmission. These connectors serve as the conduit for transferring digital signals between components, ensuring seamless communication within devices like computers, audiovisual equipment, and consumer electronics. Their robust design enables high-speed data transmission, vital in modern electronic systems.

Circular connectors form the backbone of power supply networks in electronic systems. They efficiently manage the distribution of power from sources to various components, ensuring steady and reliable electricity flow. From low-power applications like handheld devices to higher voltage systems in industrial machinery, these connectors provide a secure interface for power transmission.

In electronic systems, signal connections are crucial for the exchange of information between components. Circular connectors act as the intermediary for signal connections, maintaining signal integrity and providing a secure link between sensors, actuators, displays, and other electronic elements. Their versatility allows the transmission of various signal types, contributing to the functionality and reliability of electronic systems.

Circular connectors find extensive use in instrumentation and control systems across industries. They enable the seamless integration of sensors, probes, and control devices, facilitating precise data acquisition and control. Whether in automotive applications, aerospace systems, or industrial automation, these connectors contribute significantly to efficient system operation.

Circular connectors form the cornerstone of connectivity in electronic devices, ensuring efficient data transmission, robust power supply, and reliable signal connections critical for the functionality of diverse electronic systems.

Discover how these robust and versatile components facilitate reliable power, data, and signal transmission, thus ensuring the smooth operation of intricate machinery and systems. From heavy-duty applications in construction and manufacturing to precision tasks in automation and robotics, this section underscores the wide-ranging use of circular connectors.

Circular connectors stand as linchpins within industrial settings, powering machinery and automation systems. Their robust design and reliability make them indispensable in connecting various components, ensuring seamless operation and control in industrial machinery and automated systems.

Circular connectors play a crucial role in linking sensors and transducers within industrial setups. These connectors establish the interface between sensors and control systems, enabling the transmission of critical data for monitoring and regulating parameters like temperature, pressure, and flow. The reliability of these connections ensures precise data acquisition, contributing to enhanced operational efficiency and safety.

In industrial automation, circular connectors serve as the conduit for connecting control systems. They enable the seamless integration of control panels, PLCs (Programmable Logic Controllers), and other control devices, ensuring efficient communication and control over machinery and processes. The robust connections facilitated by these connectors are essential for maintaining operational continuity and safety.

Circular connectors serve as the backbone for connecting various machinery components and circuits in industrial settings. From motors and actuators to communication modules and power supply units, these connectors establish reliable connections, enabling the smooth functioning of complex machinery and systems.

Circular connectors, with their reliability and robustness, play a pivotal role in industrial machinery and automation by facilitating connections between sensors, control systems, and diverse machinery components, ensuring seamless operations in industrial domains.

These circular connector solutions are designed to meet specific requirements in diverse fields. Uncover how these precision-engineered components contribute to enhancing efficiency, reliability, and overall system integrity.

Engineered with sealing mechanisms and robust materials, waterproof circular connectors offer unparalleled protection against moisture ingress. These connectors find their niche in industries such as marine, outdoor electronics, and aerospace, where exposure to water or harsh weather conditions is prevalent. Their ability to maintain reliable connections in wet or humid environments makes them crucial in ensuring uninterrupted operations.

Designed to withstand extreme temperature fluctuations, high-temperature-resistant circular connectors thrive in demanding environments. Industries such as automotive, aerospace, and manufacturing, where exposure to high heat is commonplace, rely on these connectors. Their ability to endure elevated temperatures ensures reliability and consistent performance in challenging thermal conditions.

Waterproof and high-temperature-resistant circular connectors cater to the unique needs of various industries and demanding environments:

Specialised variants of circular connectors play a pivotal role in industries and environments where standard connectors might succumb to challenging conditions. Their resilience ensures uninterrupted connectivity critical for operations in demanding settings.

Circular connectors, with their impressive versatility and remarkable potential, are truly the unsung heroes of modern technology. These small but mighty components play a pivotal role in a multitude of applications, ensuring seamless communication and power transfer across an array of devices. Their durability, adaptability, and reliability made them crucial elements in ensuring seamless data transmission, power supply, and signal connections in diverse environments.

Ready to power up your systems with reliable connectivity solutions that circular connectors provide?

Explore our shop today and fulfil your electronic and industrial electrical components, cables, and equipment needs. Experience excellence in connectivity and technology with Component Buddy – your trusted partner in innovation and reliability.